Three Head Pallet Block Machine

Product Details:

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty Yes

- Usage & Applications Industrial

- Click to view more

Three Head Pallet Block Machine Price And Quantity

- 1 Unit

Three Head Pallet Block Machine Product Specifications

- Yes

- Painted

- Electricity

- Automatic

- Industrial

Three Head Pallet Block Machine Trade Information

- 10 Unit Per Month

- 20 Days

Product Description

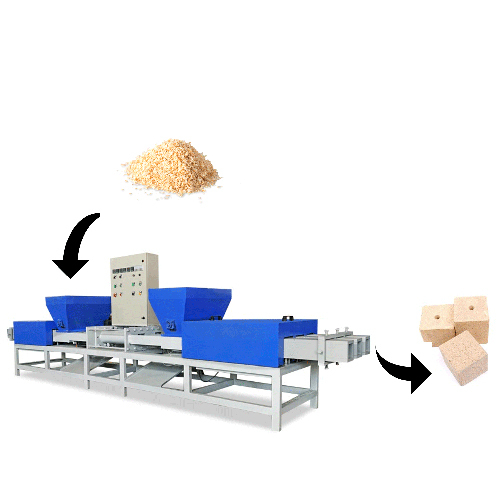

In the production process, the residual and recycled wood is processed to yield the correct chip geometry. After that, technical drying guarantees a wood humidity of less than 5%. Then, glue is applied to coarse and fine chips, they are mixed and pressed to a sturdy continuous strand. Finally, the blocks are cut out of the strand at the required height, depending on requirements and demand.

Pallet Block Features

- Free fumigation. Because the pallet block is made by hot pressing, it is free fumigation.

- Pallet block machine could recycle the wood waste efficiently.

- The density of the final product could get to 550-1000 kg/m3.

- Normal Pallet block size are 90*90mm, 90*100mm, 100*100mm, 80*90mm.

Pallet block machine is used to produce wood pallet blocks, also called compressed wood block making machine. Pallet block making machine mainly includes three types of specifications: single-head pallet block machine, double-head wood pallet block machine, and triple-head hot press wood pallet block making machine.

Pallet Block Making line:

- Wood Crushing Machine, as name as hammer mill, processing the wood particles into wood sawdust.

- Wood dryer,air flew dryer and rotated dryer available for different capacity

- Material Storage Silo for the material storage after drying.

- Glue Mixer: mixing the material with glue with a certain ratio.

- Pallet block machine to make the block.Size available range from 75mm to 145mm. Besides, one machine could make two different sizes block.

- Block cutter, cut the block into request length.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+