Showroom

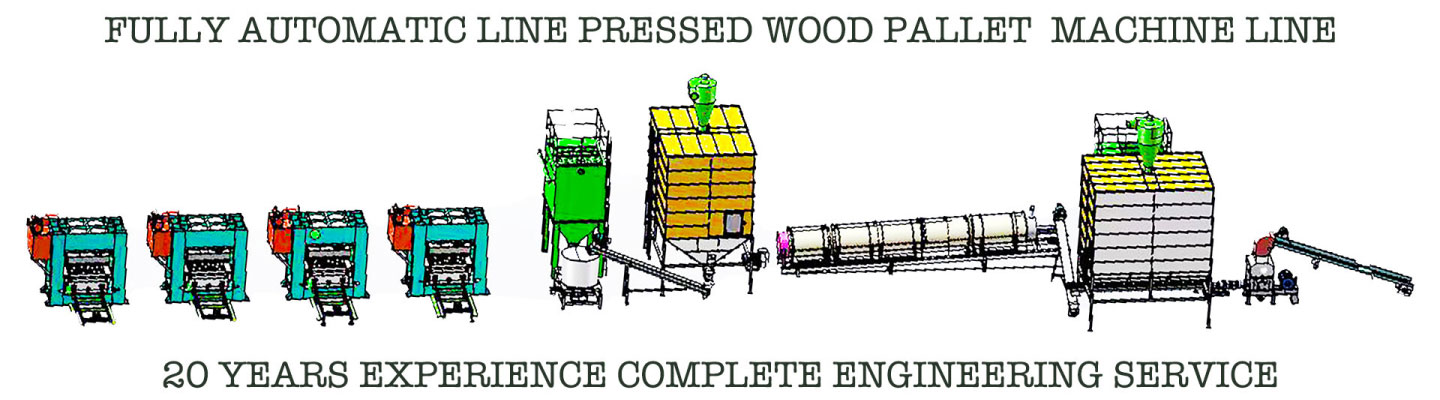

Crafted from durable metal, pressed wood pallet machinery features meticulous painted treatment for longevity. Operating on 220-440 volts, it integrates precision engineering for optimal performance. Automating wood fiber compression, it yields sturdy pallets, enhancing productivity and minimizing manual labor. Versatile and eco-friendly, it meets diverse industrial demands, epitomizing innovation in pallet manufacturing.

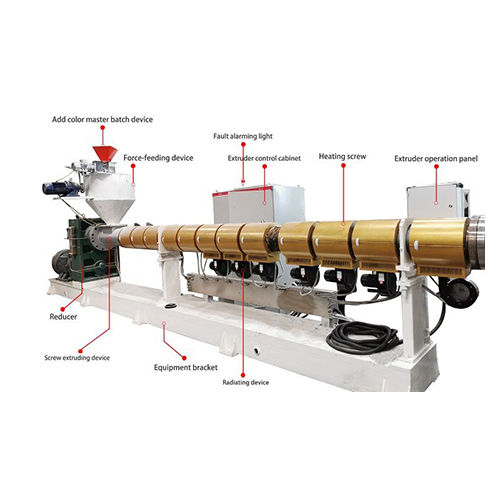

Precision-crafted, the pressed plastic pallet machinery boasts painted surface treatment for durability. With 1200 tons of pressure and CNC technology, it ensures accuracy. Electrically powered, it offers a 1-year warranty and caters to industrial needs, reducing labor costs and enhancing productivity. Versatile and durable, it embodies innovation in pallet production.

Electrically driven, cable reel machinery operates at 50 Hertz, ensuring consistent performance and enduring temperatures down to 150 degrees. With a 300-350 second pressing time for urea formaldehyde, it delivers precise manufacturing. Robustly designed, it optimizes production in cable manufacturing, reducing downtime, and enhancing output, pivotal for seamless processes.

Pallet block machinery produces dense blocks with 550 to 1000 kg/m³ density. Sizes range from 90x90mm to 100x100mm. Semi-automatic with CNC technology and electric power, it's ideal for industrial use, efficiently meeting size requirements. Its painted surface enhances durability, ensuring uniformity and quality while streamlining pallet production for enhanced efficiency and reliability.

Auxiliary equipment like Air Flow Dryer, Wood Chipper Machine, and Tube Bundle Dryer enhance industrial processes with superior performance and reliability. They efficiently remove moisture, process raw materials, and ensure thorough drying, improving output and product quality while reducing processing time and enhancing operational efficiency across industries.

The Paper Core Plug Making Machine, powered by electricity, operates automatically with a painted surface. It comes with a warranty and is used in industrial settings, enduring temperatures of at least 150 degrees. Each batch takes 20-30 minutes for pressing. This machine efficiently produces paper core plugs, ensuring reliability and precision in manufacturing processes.